FuelRx

Producing premium diesel fuel conditioner since 2002.

Combustion

Enhancement Technology

Real

World Testing

ABOUT US

20 YEARS OF EXPERIENCE

FuelRx was founded in 2002. Its mission was to develop an advanced product for the automotive industry. One that would fully clean and continually lubricate an engine before & after combustion, while simultaneously lowering emissions.

From its introduction through to the present formulation, FuelRx has undergone extensive “real world” testing in a wide range of operational environments. Proving repeatedly, to enhance performance, lower emissions and increase cost effectiveness.

FuelRx is a premium diesel fuel conditioner that has been proven to reduce fuel consumption by 5% – 10%, reduce particulate emissions by 50% and cut gaseous emissions by 20% or more, while addressing the lubricity issue that is present in today’s low sulphur diesel fuels. It not only cleans and lubricates, its advanced Combustion Enhancement Technology improves combustion without the use of solvents or by increasing cetane levels.

FuelRx is a premium diesel fuel conditioner that has been proven to reduce fuel consumption by 5% – 10%, reduce particulate emissions by 50% and cut gaseous emissions by 20% or more, while addressing the lubricity issue that is present in today’s low sulphur diesel fuels. It not only cleans and lubricates, its advanced Combustion Enhancement Technology improves combustion without the use of solvents or by increasing cetane levels.

FuelRx has been used in the retail automotive market for over a decade in the UK. With the success of our diesel conditioner, we decided to create an additional product for the Heavy Industry sector. One designed and formulated specifically for use with Bunker C (#6) heavy oils.

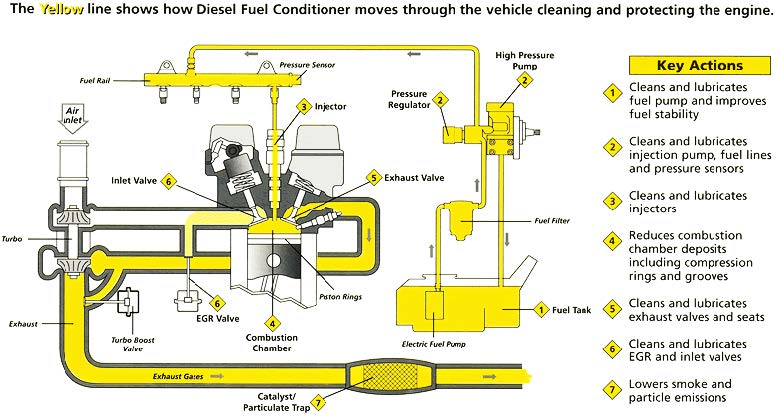

HOW THE PRODUCT WORKS

Modern ULS Diesel contains up to 10 times more water than it has in the past as well as containing 5% Bio Diesel (which absorbs water). Water, fuel plus oxygen, creates acid. Acid in the fuel system leads to build-up of gums, tars and varnishes. Which allows carbon deposits to gain a purchase and leads to reduced component life, inefficient fuel delivery and fuel burn. As lubrication within the fuel has also been greatly affected by the reduction of sulphur which majorly impacts component wear.

Modern ULS Diesel contains up to 10 times more water than it has in the past as well as containing 5% Bio Diesel (which absorbs water). Water, fuel plus oxygen, creates acid. Acid in the fuel system leads to build-up of gums, tars and varnishes. Which allows carbon deposits to gain a purchase and leads to reduced component life, inefficient fuel delivery and fuel burn. As lubrication within the fuel has also been greatly affected by the reduction of sulphur which majorly impacts component wear.

FuelRx has been formulated to deal with many different factors affecting fuel quality as well as the efficiency of fuel delivery to the combustion process. As no solvents are used as active ingredients, (these can burn off during the combustion process), FuelRx is able to carry on working through the E.G.R. and exhaust processes thus ensuring a thorough clean is achieved and maintained. Fuel burn time is also fractionally enhanced, creating more power without increasing cetane value.

Other manufacturers use solvents, as they are cheap and provide a quick clean. Unfortunately this comes at a cost to the end user. All lubrication is stripped by the solvents during the cleaning process; increasing wear on components and where gums, tars, varnishes and carbon build up have taken place imperfections occur between the deposits and surfaces.

Future deposits are then able to build up more quickly, as they gain a purchase on these imperfections. FuelRx’s integrated surface modifier instead creates a lubricated barrier, thus preventing future build up. FuelRx provides a “clean and stay clean” process.

Water

This is chemically encapsulated by FuelRx and amalgamated into the fuel. It is then passed through the combustion process and out through the exhaust with no ill effects to the system.

Carbon Build Up, Gums, Tars & Varnishes

Lubrication Packs

Surface Modifiers

FEATURES & BENEFITS

FuelRx will:

- Clean all combustion areas

- Increase combustion by cleaning the entire fuel system including the injector nozzles and create a fractionally longer burn to sustain more complete combustion

- Lubricate the entire fuel system

- Clean the injectors

- Increase economy (5-10% fuel saving)

- Reduce down time

- Reduce toxic and greenhouse emissions, offering a cost effective solution to carbon build up and emission control.

MarineRx

Warships

Merchant Container Ships

Cruise Ship Vessels

FEATURES & BENEFITS

- Reduces Carbon Emissions

- Reduces NOx & SOx

- Increases Service Life

- Lubricates Fuel & Combustion Systems

- Cleans Spark Plugs (GFx)

- Encapsulates metal contaminants and passes them through the combustion process

- Encapsulates water and passes it through the combustion process

- Increases Efficiency

- Reduces Downtime

- Biocide kills off “Diesel Bug”

- Surface modifies interior of Fuel System, Combustion Chamber and Exhaust System

Water Ingress is a very common occurrence in a boat’s fuel tank. Diesel can sweat, causing water droplets to form. Alternatively, water may enter via the tank ventilation system during ambient air renewal. As it is denser than diesel, water naturally sinks to the bottom of the tank with the diesel sitting on top.

The “Diesel Bug” sometimes known as the “HUM Bug” (Hydrocarbon Utilizing Micro-organisms) sits between the water and diesel layers in the fuel tank and feeds on the hydrocarbons within the fuel. As the fuel is sucked up through the system, the Diesel Bugs get caught up and clog the filters. FuelRx Marine works by killing the bugs, encapsulating the water and feeding it back into the diesel.

Once the bugs are gone they stay gone as any future water contamination is immediately rectified.